Polityka bezpieczeństwa (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

Zasady dostawy (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

Zasady zwrotu (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

Die einseitig dauermagnetischen Schraubstöcke der Serie TMJ haben ein breites Anwendungsspektrum bei Schleif-, Schneid-, Bohr- und Fräsarbeiten sowohl auf konventionellen als auch auf CNC-Werkzeugmaschinen. Der Schraubstock ist auf der Basis von langlebigen Neodym-Magneten gebaut. Er benötigt keine elektrische Energieversorgung und ist daher für den Benutzer völlig sicher.

Der Körper des Spannfutters besteht aus einem einheitlichen Stahlblock, an dem zwei Polstücke angeschraubt sind. Zusätzlich sind auf den Polschuhen exzentrische Dichtungsplatten montiert, um ein Werkstück bei hohen Bearbeitungskräften besser in der horizontalen Ebene zu spannen. Das Magnetfeld kann mit Hilfe eines Steckschlüssels durch Drehen um 180° nach rechts bzw. links ein- und ausgeschaltet werden.

Universelle einseitige Magnetspannstöcke sind für das Spannen von ferromagnetischen Werkstücken (Eisen, Baustahl, legierter Stahl, Gusseisen) ausgelegt. Die Steifigkeit des Schraubstocks und die Kraft der Neodym-Magnete ermöglichen das Spannen schwerer Werkstücke, während die geringen Abmessungen die Bearbeitung eines Werkstücks von fünf Seiten in einer einzigen Spannposition erlauben. Die Schraubstöcke der Serie TMJ sind beständig gegen Wasser und Kühlmittel mit einem pH-Wert > 8,7.

Die beidseitigen Drehpunkte der Magnetrolle ermöglichen die Kombination von zwei oder mehr Schraubstöcken zu einem Satz, wodurch lange Werkstücke gespannt werden können.

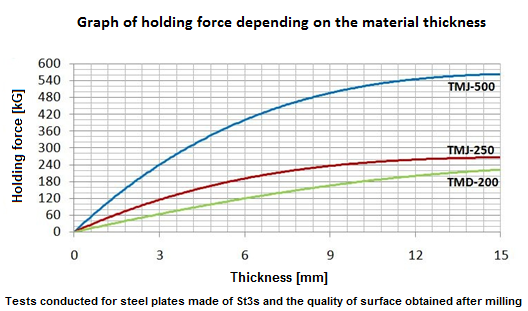

Parameter, die Spannkraft beeinflussen:

Form der eingespannten Werkstücke - um die volle Haltekraft zu erreichen, sollte die Größe des eingespannten Werkstücks nicht kleiner sein als der Arbeitsbereich des Futters.

Schematische Darstellung und Abmessungen der verfügbaren TMJ-Futter sind unten dargestellt:

| Typ des Magnetspannplatte | Abmessungen [mm] | Gewicht [kg] | ||||||

| A | B | L | W | H | C | D | ||

| TMJ-250 | 102 | 106 | 142 | 128 | 65 | 55 | 115 | 4,7 |

| TMJ-500 | 110 | 150 | 200 | 150 | 76 | - | - | 9,3 |