- Sale!

- Out-of-Stock

Polityka bezpieczeństwa (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

Zasady dostawy (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

Zasady zwrotu (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

TSSE series electro-permanent magnetic chucks are the latest achievements in the ferromagnetic workpiece clamping technology. A huge clamping force is achieved through the use of neodymium and alnico magnets induced by a current pulse. The chuck is supplied with an alternating current with a voltage of 400 V and frequency of 45-65 Hz. The device has the IP43 protection class. It can be controlled directly via the included controller, wired remote control or via a PLC controller (picture below):

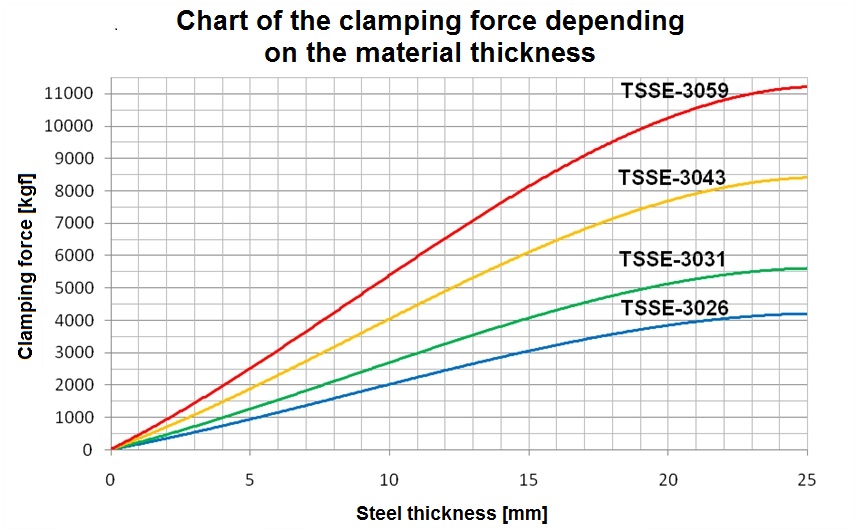

The chuck has adjustable clamping force within the range of 1-8 and can be used in sets (controlled by a single controller) for clamping large workpieces. As a standard, the kit is equipped with a controller for 1 chuck, but it is possible to order a controller that can control two or more chucks simultaneously, so the size of workpieces to be clamped is unlimited.

If the chucks offered by us do not match your requirements, it is possible to order a chuck with a requested size.

The design of the device ensures a high level of safety for the user, which results from the possibility to disconnect the power supply (the possibility to disconnect the power supply after magnetization), as well as a high energy efficiency even up to 95% as compared with electromagnetic chucks (which require continuous power supply). Magnetic fields, which do not come into contact with the workpiece clamped, are not magnetized. Due to a uniform structure of the body of the chuck, the device is extremely rigid and durable, while the precise workmanship guarantees a high accuracy of workpiece machining. The working surface consists of square magnetic fields with a size of 50 x 50 mm, isolated from each other with a layer of epoxy resin. Magnetic poles are arranged interchangeably in a checker pattern. In the case of extreme parameters of machining, eccentric stops mounted on edges of the chuck can be used to additionally fix the workpiece to be machined. The design of the chuck allows machining a workpiece from five sides in a single clamping position. The chuck is also equipped with additional circular pole pieces that enable through hole drilling (to protect the chuck against damage) and allow clamping workpieces with irregular shapes. In order to increase the accuracy of machining, it is also recommended to use floating pole pieces.

However, the biggest advantages of TSSE chucks include the possibility to automate the operation of the chuck and synchronize it with a machine tool, as well as the possibility to disconnect the power supply when machining. Due to the fact that the condition of the working surface has a very large impact on the clamping force, the working surface can be regenerated by grinding - even up to 5 mm of the chuck thickness.

A schematic diagram of the chuck, which shows also how to connect its elements into one set, is shown below:

The operating manual is in the attachment.