- Out-of-Stock

Polityka bezpieczeństwa (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

Zasady dostawy (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

Zasady zwrotu (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

The TSS magnetic chucks with increased holding force are designed for fastening ferromagnetic workpieces with a smooth surface (the lower the roughness, the greater the holding force) both for ‘dry operation’ and for operation in cooling water. The magnetic chucks can be used for grinding, electro-sinking, milling and electro-erosion cutting machines or for auxiliary fastening of ferromagnetic workpieces.

The magnetic chucks from the TSS series are manufactured on the basis of neodymium magnets. The clamping surface consists of magnetic poles arranged alternately in a chequerboard pattern and separated from each other by epoxy resin. The magnetic field is switched on by rotating the lever by 180o.

The base plate (base) is made of a solid steel block, which makes the magnetic chuck construction rigid and firm and allows very precise fixing of workpieces.

There is no power supply, which guarantees complete safety for the user. The full holding force can be achieved by placing the workpieces on at least two neighbouring magnetic poles so that the element to be held closes the magnetic circuit. The minimum dimensions of the workpiece to be attached should be 40 x 18 mm.

The adhesive force is at least 25 kG / 1 magnetic pole (one magnetic pole has the dimensions 18 x 18 mm). This means that a workpiece with a thickness of at least 6 mm covers 10 magnetic fields.

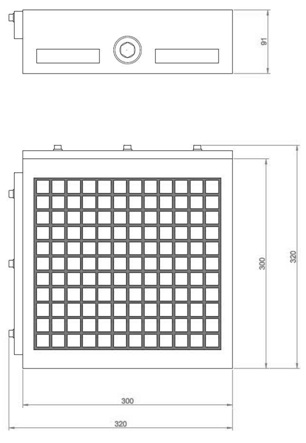

The arrangement of the magnetic fields is shown below:

TSS magnetic chucks Dimensions:

Properties that influence the adhesive force:

Type of material - the adhesive force increases in direct proportion to the iron content in the steel:

- low-carbon steel: 100%

- high-carbon steel: 90%

- low-alloy steel: 75%

- cast iron: 50%

The parameters of the clamping surface:

|

Length of the magnetic chuck [mm] |

Deviation of the flatness of the magnetic chuck [mm] |

Parallelism of magnetic chuck [mm] |

|

≤ 400 |

0,020 |

0,030 |

|

> 400 ≤ 630 |

0,025 |

0,040 |

|

> 630 ≤ 1000 |

0,030 |

0,050 |

*) For the investigation of the magnetic clamping plates, ground steel

plates made of steel (St3s) with the dimensions 50x50 mm were used.

The packaging contains the following elements:

- Magnetic chuck

- Stop bar with fastening screws (1 or 2 sets depending on the type of magnetic chuck)

- Fixing clamps with screws (4 sets)

- Allen key for switching the magnetic field on and off.