Polityka bezpieczeństwa (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

Zasady dostawy (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

Zasady zwrotu (edytuj za pomocą modułu „Bezpieczeństwo klienta”)

TSJ series rectangular permanent magnetic sine chucks are designed to clamp ferromagnetic workpieces (i.e. iron, structural steel, alloy steel, cast iron) during grinding, milling and electrical discharge machining in a horizontal position and at the angle of 52°. The body of the chuck consists of a single block of steel, while its top plate is made from steel and brass lamellas placed interchangeably. The steel base ensures a high rigidity and thus also a high accuracy of grinding. TSJ series chucks use neodymium magnets, thanks to which the maximum clamping force is obtained.

The chuck can be set at a required angle by placing gauge blocks between the base of the chuck and its support roller (the height of blocks is selected according to the table attached to the manual). Another way to set a required angle is to use a precision protractor.

The rigid structure of the chuck enables very precise machining, while its tightness allows using the chuck for operations involving coolant or operations in full submersion. In order to make it easier to clamp workpieces at an angle, the chuck has a stop rail useful in positioning.

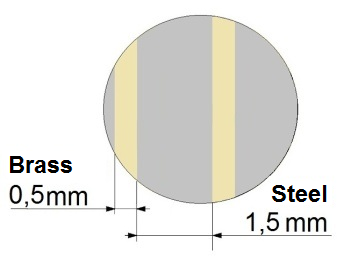

The pole pitch (1.5 ± 0.5 mm) allows holding workpieces of different sizes. Pole pitch diagram:

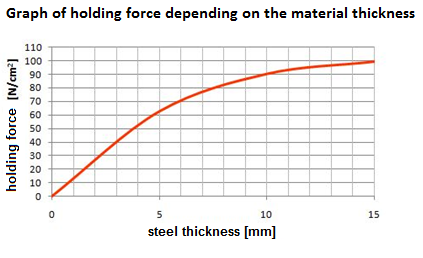

The clamping force depends on the following parameters:

The rectangular permanent magnetic sine chucks available in our offer are presented below:

|

Chuck type |

Dimensions [mm] |

Weight [kg] |

|||||

|

A |

L |

B |

D |

H |

Pole pitch |

||

|

TSJ-1515A |

200 |

150 |

150 |

100 |

90 |

1,5+0,5 |

16,0 |

|

TSJ-1710A |

225 |

175 |

100 |

75 |

85 |

1,5+0,5 |

12,0 |

|

TSJ-3015A |

350 |

300 |

150 |

100 |

95 |

1,5+0,5 |

31,0 |

- magnetic chuck

- stop rails with bolts - 2 sets

- Allen wrench to turn on the magnetic field - 1 piece